Appendix: Conventional Lasers and their Issue

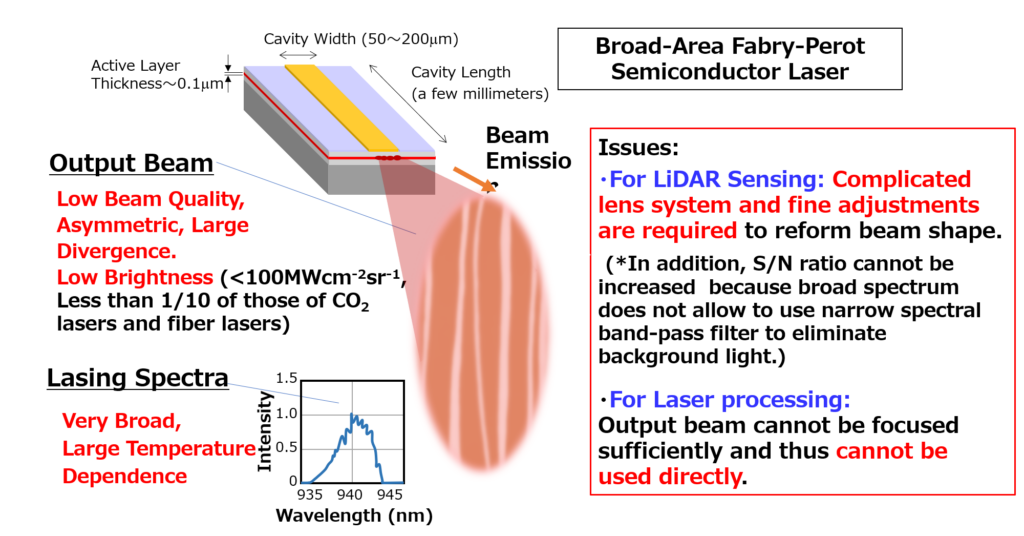

Conventional semiconductor laser (broad-area Fabry-Perot semiconductor laser)

For high power operation, the cavity width is made larger to 50 to 200um to increase the output power. Thus, the output beam becomes low quality, and due to the fundamental nature of edge-emitting laser, output beam is asymmetric and has large divergence. The low beam quality leads to low brightness, which is less than 100MWcm-2sr-1, and this value is less than 1/10 of it of CO2 lasers and fiber lasers. In addition, the lasing spectrum is very broad and has a large temperature dependence. Thus, issues for applications are as follows.

– For LiDAR sensing, a complicated les system and fine adjustments are required.

– For Laser processing, the output beam cannot be focused sufficiently, and thus cannot be used directly.

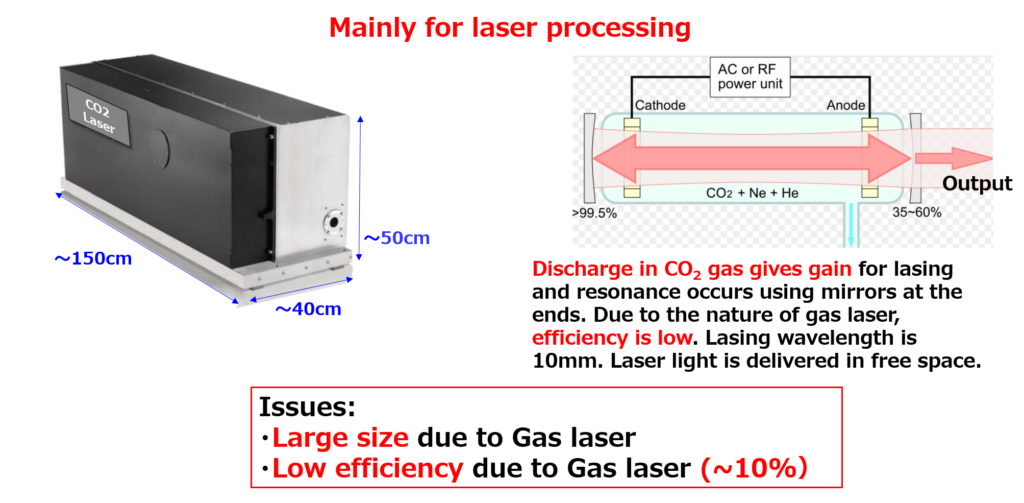

CO2 laser

In CO2 lasers, the discharge in CO2 gas gives the gain for lasing. Such CO2 lasers are mainly utilized for laser processing. The size of this type of laser is very large; around 1 cubic meter. Due to the nature of gas lasers, the efficiency is low; about 10%. So the issues are large size and low efficiency.

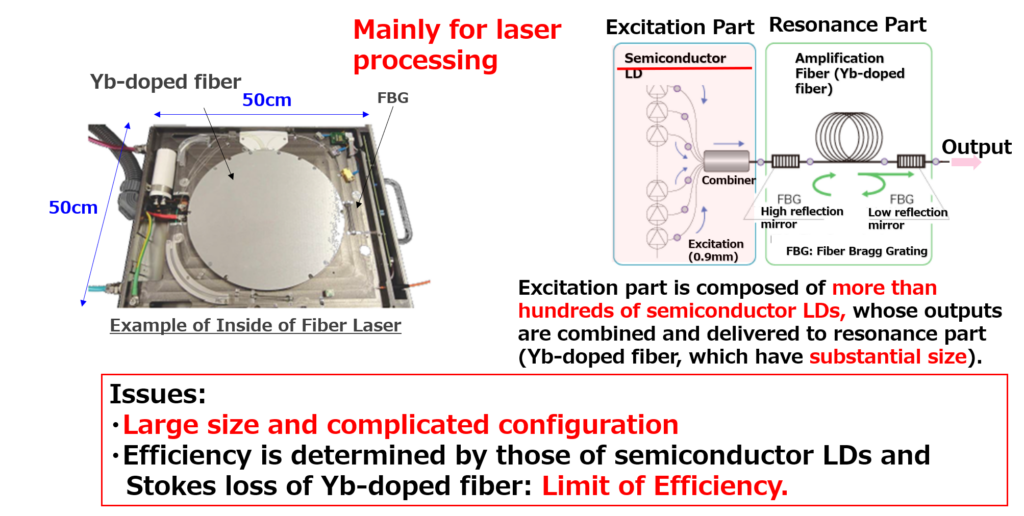

Fiber laser

Fiber lasers are also utilized mainly for laser processing. Their size is again very large as CO2laser. Fiber lasers are constructed by two parts; excitation part and resonant part. The excitation part is composed of hundreds of semiconductor lasers, so many semiconductors, whose outputs are combined and delivered to resonance part composed of the fiber which has also a substantial size. Thus, the issues are in the large size and the complicated configuration. In addition, the efficiency is determined by those of semiconductor lasers and Stokes loss of the Yb-doped fiber; thus, efficiency is limited to around 40%.